Project-Ruining Power Tool Mistakes to Avoid

We’ve come a long way from the days of stone axes and picks, but the human capacity for silliness has never changed. In this post, we’ll take you through some common power tool mistakes that could be hindering your progress on your project.

Dull Blades and Bits

Power tools are great for drilling a few holes and cutting a few edges. You know what’s not great, though? Having to spend five minutes drilling a single hole because the drill bit you used was too dull. It seems obvious, but it’s always a good idea to just check that all your bits and blades are still sharp enough for the job at hand.

Neglecting Safety Gear

Who would have thought that the rotating blades and spinning bits would be dangerous? Fortunately, some bright individuals invented safety equipment way back when to prevent the loss of limbs and appendages. And you can be bright, too, so long as you actually use the equipment.

Changing Blades (while Plugged In)

When one of your blades begins to lose its edge, you’ll naturally want to change it as soon as possible. That being said, you don’t want to make the mistake of changing it while the tool is still plugged. Accidental activation can quickly lead to some nasty injuries.

Working From Unstable Positions

Taking on any project that necessitates the use of power tools is always going to come with some danger, but taking the right cautionary measures can prevent you from coming to any harm. That means always working from a stable position and not overreaching for a spot that you simply can’t get to.

Using the Wrong Tools

While power tools generally have really simple functions and uses, they come in many different varieties with subtle differences that make certain tools better for certain tasks. For example, you don’t want to use a drill to drive screws instead of an impact driver; doing so could damage the tools, not to mention make what should be a simple job take that much longer.

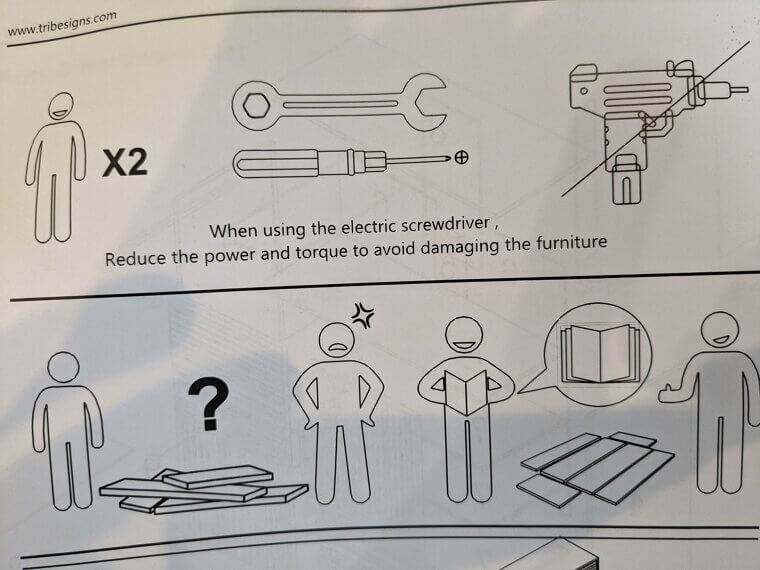

Ignoring Instructions

As we’ve already established, power tools have pretty simple functions, but the actual application of those tools requires a bit of finesse - and, more importantly, the right know-how. Always consult the manufacturer’s instructions manual to avoid damaging your tools - and yourself.

Overloading Tools

For a set of instruments called power tools, you’d be surprised by how many of them need a bit of rest every now and then. Indeed, you’ll want to avoid overloading your tools to prevent them from becoming damaged or ineffective in the long run.

Using Damaged Cords

Like pretty much every gizmo and doo-dad nowadays, power tools are useless without a power supply. You’ve likely got tons of cords and cables lying around already, but when working with these tools, you’ll want to ensure that the cord is still intact. Exposed wires can cause electrical shocks and fires.

Improper Security

Many people think that working with power tools doesn’t require much in the way of dexterity and finesse. In fact, as anyone who has ever attempted their own project will tell you, it requires plenty of precision and care, and that extends to the materials you use, which should always be kept as secure as possible.

Working Without Training

Don’t get the wrong idea - we don’t want to dissuade anyone from working with power tools on their own projects. Like any skill, however, working with these tools requires a bit of practice - training, if you will - and failing to do so can lead to some terrible accidents.

Freehand Cutting With a Table Saw

Table saws are great for quickly cutting large pieces of material, but if you’ve ever seen a horror movie or slasher film, you’ll know that they can also be instruments of injury and death. For that reason, we recommend you always use the rip fence when cutting anything with a table saw to prevent a loss of control - and injury.

Cutting Short Pieces With a Miter Saw

Miter saws are great tools for making quick and precise cuts at specific angles, but as with any tool, there are times when they may not be as effective, like cutting small pieces. The pieces can easily get caught in the device, potentially leading to binding and injury.

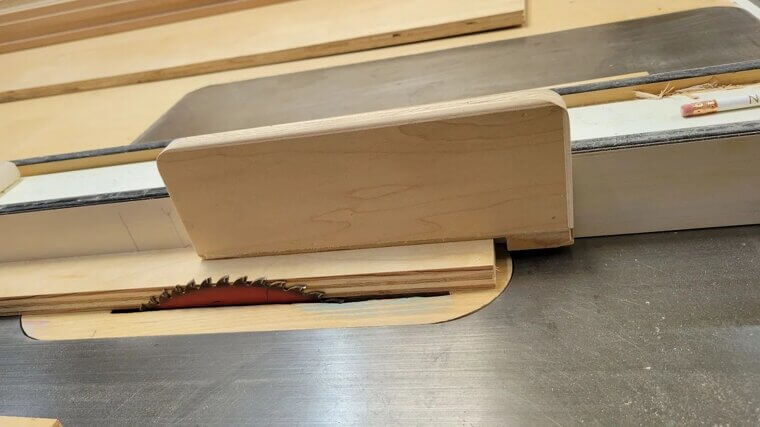

Not Using a Push Stick

Push sticks won’t always be necessary, but when handling large pieces and heavy machinery, you’ll always be glad to have one by your side. Our advice: better safe than sorry. Failing to use a push stick at the wrong time can cost you dearly.

Forcing

Hopefully, by now, we can all agree that power tools are, in fact, pretty powerful. Still, they have their limits, and there are times when your saw just isn’t cutting it - literally! When this happens, you shouldn’t try to force a material through, as this can lead to binding and kickback.

Cutting Without Support

As previously mentioned, power tools actually require plenty of precision to get the best results. That means ensuring that everything is in its right place before you get to work - including your materials. You’ll want to make sure they’re properly supported before attempting anything, lest you end up with jagged edges and oddly-angled cuts.

Dull Blades for Cutting

When using power tools like saws (which use blades), we encourage you to think of yourself as a Medieval knight or samurai: you’re only as good as the sharpness of your blade. Using dull blades for cutting can lead to rough edges and also require much more effort to work with.

Not Measuring Twice

Once again, the keyword is “precision”. Whatever project you’re working on, whether it be big or small, you’ll want the end result to be the way you envisioned it. That requires a good deal of planning and accuracy, so, as the old saying goes: “Measure twice, cut once”.

Ignoring Wood Grain

Wood grain are those little patterns that adorn every piece of wood that you work with. They’re like rivers - they generally “flow” in one direction, and the better you are at following this, the better the end result will be. In woodworking, this is one time you don’t want to be going against the grain.

Using the Wrong Blade

Certain materials require specific tools to work with. Luckily, this isn’t too difficult to discern - you don’t want to use a woodcutter for a sheet of metal and vice versa. Ensuring that you’re always using the correct tools will also ensure that you get the best results.

Not Using a Vise

Think of vises and clamps as a bit like paperweights for the material you’re working with. They prevent the thing from moving, which allows you to be super precise with your work while also safeguarding against injury. After all, your material just needs to shift a little bit for things to go wrong.

Using the Wrong Drill Bit

Your drill is kind of like a weapon in that it’s pretty dangerous but also pretty customizable. Like putting on a silencer for a quiet takedown, your drill can be equipped with several bits that serve different purposes. You wouldn’t want to use a wood bit for a sheet of metal lest you damage both the bit and the material itself.

Not Drilling Pilot Holes

Pilot holes are important for ensuring that whatever material you’re working with (typically wood) doesn’t split or crack. They also help you accurately guide the screw into place, so don’t make the mistake of not drilling a pilot hole when it’s necessary.

Overdriving Screws

Screws help secure different materials into place, so it’s only natural that you’d want to ensure that the screws themselves are secure as well. With that being said, you’ll want to avoid overdriving the screws, which can cause damage to the material while also stripping the hole.

Using an Underpowered Battery

While it’s true that most power tools you use need to be plugged in in order to function, most of them also have batteries, too. For that reason, you’ll want to ensure that these batteries are kept fully powered - failing to do so could cause the tool to stall or otherwise perform totally inefficiently.

Not Adjusting the Torque

Torque is the metric we use to measure how much or how little twisting force a tool is capable of. You’ll be making use of different torque settings for different materials - a metal sheet requires more torque than a piece of wood.

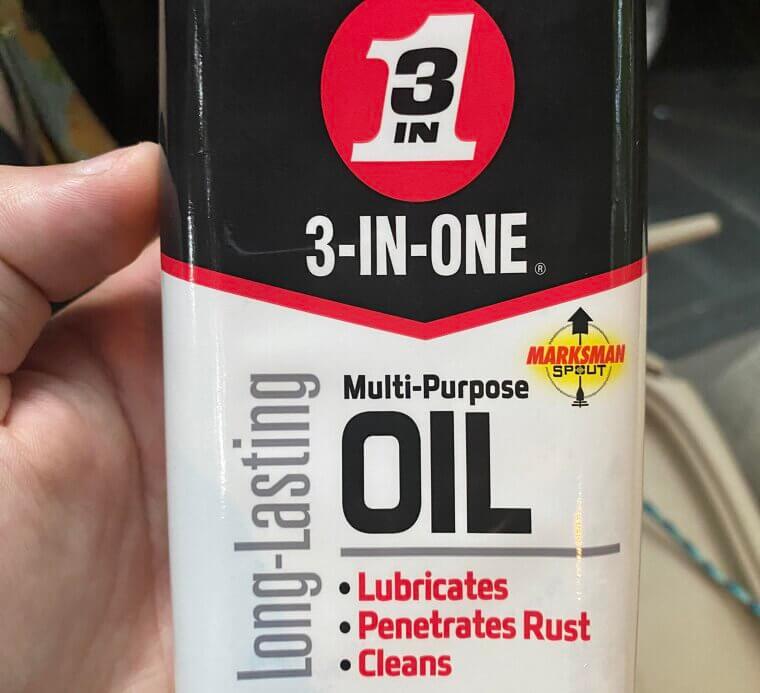

Drilling Without Lubrication

Although you can get away with drilling a few holes into your sheet of metal “raw”, you should always use some form of lubrication to avoid damaging the bit and prevent it from overheating during the drilling process.

Not Using the Hammer Function

While masonry is a fairly niche interest, many power drills nowadays nevertheless include a hammer function, which essentially allows the drill to hammer even as it rotates. You shouldn’t attempt masonry otherwise, lest your drill end up damaged.

Not Securing Drill Bits

Drill bits work similarly to bottle caps in that they have to be screwed and unscrewed, and, just like bottle caps, you’ll definitely want them to be screwed on tight. Insecure drill bits are prone to slipping, which can lead to inaccurate holes and injury.

Using the Drill in the Wrong Direction

Drills rotate in two directions: the right direction tightens the screws, while the left loosens them. It seems like fairly obvious advice to give, but seriously, just make sure you’ve got your drill set to the right direction for the job you’re doing.

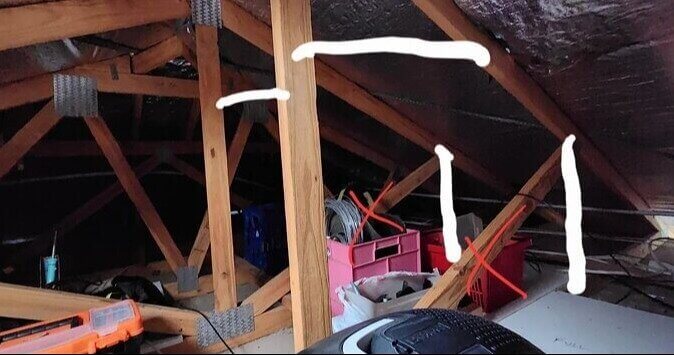

Not Checking for Utilities

If you’re drilling into an existing surface or structure, always be sure to check behind it for any hidden wires or pipes. You could accidentally drill into one of them, damaging your utilities and leaving you with a pretty hefty repair bill.

Not Cleaning Tools

Like just about anything that you work with, over time your tools will eventually get dirtier and dirtier. Allowing the dirt to build up for too long can cause issues with your tools, stalling them and rendering them ineffective.

Not Handling With Care

It seems obvious, but power tools (and tools in general, really) should always be used with care. When they’re not actively in use, place them in a secure area, and when handling them, make sure you’re holding them correctly and keeping their sharp bits away from yourself.

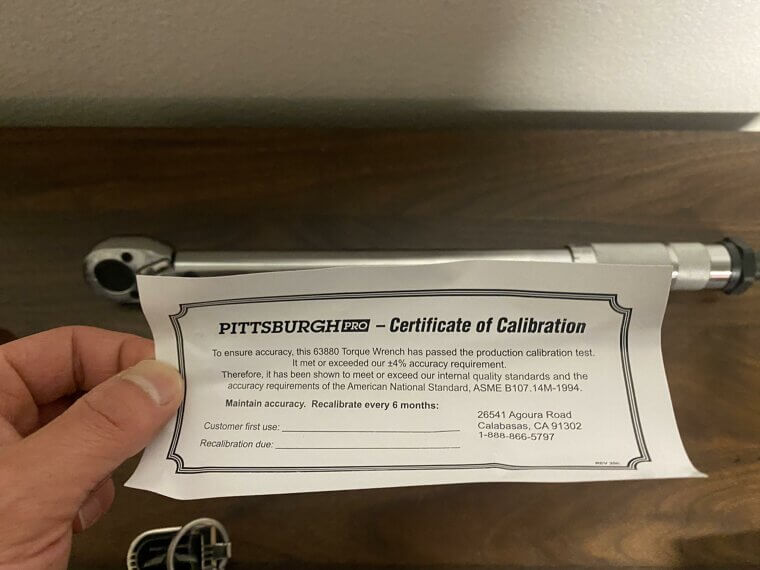

Ignoring Calibration

Although power tools are simple in function, their internal mechanisms are incredibly complex and will occasionally need to be recalibrated. Failing to do so can lead to inaccuracies in measurements and rough cuts.

Ignoring Proper Storage

Tools, like any instrument, should be stored safely and properly. This not only prevents injury but also keeps them in good shape, allowing them to function for longer before requiring repairs - or worse, replacement.

Not Allowing Tools to Cool Down

The longer you use certain tools, the hotter they’ll generally become. This can prevent you from storing them safely, as well as cause other issues, should you continue to use them without allowing them to cool down first.