Wire Stripper / Crimper

Stop nicking the wire! The stripper has multiple holes corresponding to specific wire gauges. You must match the gauge exactly, close the jaws, and pull the insulation off. If you turn the tool or use the wrong hole, you risk nicking the conductive copper strand underneath.

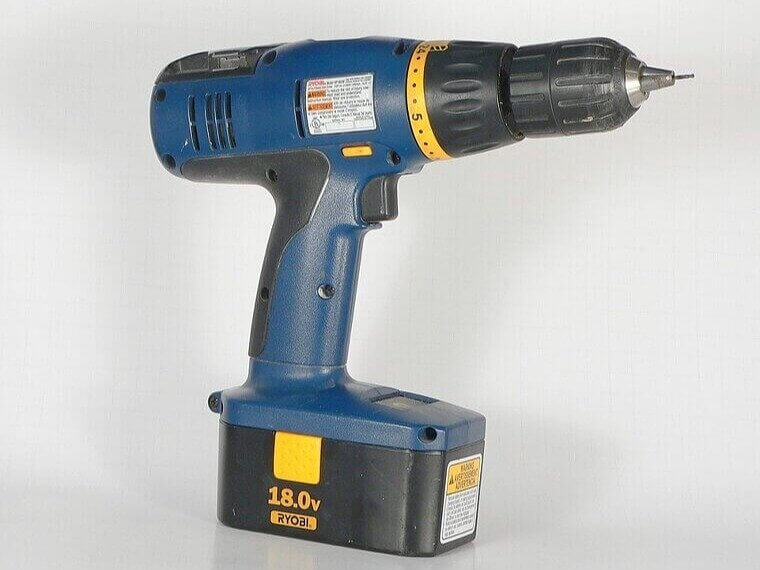

Cordless Drill / Driver

This MVP of the DIY world does so much more than drill holes, but many neglect its clutch settings. Use the numbered dial to set the torque limit or stop the screw from burying itself too deeply into the material.

Impact Driver

Many people use this for everything, but it excels at one thing: driving long fasteners. Its unique rotational hammer action delivers rapid, powerful bursts of force, meaning you don't have to lean into the tool.

Circular Saw

There’s no magic to making straight cuts. Many DIYers skip the guide rail, cut unsupported wood, or push too fast, ending up with splintered edges. Set your blade depth just below the material thickness and keep a steady pace.

You should give these tricks a go this weekend!

You should give these tricks a go this weekend!

Oscillating Multi-Tool

It sands, it scrapes, it cuts, it grinds, but only if you pick the right attachment and let the oscillations work instead of forcing them. The key to a clean cut is selecting the correct blade for the job and ensuring it is sharp.

Random Orbital Sander

Are you getting those swirling scratch marks? That’s a speed/pressure problem. Most users press too hard or skip grits. Start coarse, move progressively finer, and keep the sander moving for a finish you’ll actually want to run your hand across.

Complete Drill Bit Set

You’ve got the set, but can’t get the results? Try to match the bit material and geometry to the target surface. A masonry bit is useless on metal, and using a wood bit on metal will quickly ruin the edge and cause the bit to overheat.

A few tweaks now can save hours of frustration…

A few tweaks now can save hours of frustration…

Adjustable Wrench

This tool only works if you tighten the jaws snugly onto the fastener head. The force must be applied in the direction of the fixed jaw (the one that doesn't move) to prevent the wrench from slipping.

Stud Finder

Most DIYers forget to calibrate it! You must turn the device on while holding it flat against the wall in a stud-free zone (usually away from corners). Scan slowly and mark both edges to find the true center.

Leveler

Don't just trust the bubble! The bubble may tell you if something is level, but it doesn't account for crooked walls. Use the level to draw a straight line, then measure from a consistent reference point.

The difference between an amateur and an expert is knowing their tool’s capabilities…

The difference between an amateur and an expert is knowing their tool’s capabilities…

Putty Knife

The technique depends on the task. Use a flexible blade for smoothing spackle into a nail hole or crack. Use a stiffer blade for scraping off old material. When spackling, apply the compound and use a second, clean pass to smooth the edges.

Bar Clamp / C-Clamp

Less is more in this case. The common error most people make is over-tightening. You only need enough pressure to secure the workpiece or close a glue joint until a thin bead of glue squeezes out.

The next tips might not be what you expect…

The next tips might not be what you expect…

Utility Knife / Box Cutter

Snapping blades at the wrong time, cutting toward your hand, or pushing too hard are classic rookie mistakes. Extend only one segment of the blade, score lightly, and make multiple passes. You’ll get cleaner cuts and get to keep all your fingers.

Torque Wrench

This is a measurement tool, not a loosening tool. Never use a torque wrench to break loose a stubborn bolt; this can damage the internal spring mechanism, throwing off its accuracy. Only use it for tightening to a precise, pre-set force value.

Needle-Nose Pliers

They’re perfect for grabbing wires or tiny fasteners, but only if you use the tip for precision and the inner jaws for grip. Don't use them to twist large, heavy nuts or bolts; the jaws are too small and lack grip strength.

You’re probably doing this next one wrong…

You’re probably doing this next one wrong…

Paint Roller and Tray

Most people drown the roller, then squeeze paint out while rolling. Instead, load evenly, roll off excess on the ridged area of the tray, and apply in overlapping “W” strokes, giving your walls uniform coverage without drips.

Multi-Bit Screwdriver

Always lock the bit in fully before turning, match the bit size to the screw head, and keep downward pressure steady. This prevents cam-out and chewed screw heads, making your “all-in-one” driver actually perform like the name promises.

You’ve already got the tools. It’s time you nail the technique…

You’ve already got the tools. It’s time you nail the technique…

Leveling Shims

Shims are for fine-tuning, not filling huge gaps. They must be trimmed to fit discreetly inside a door or window jamb. Done right, shims can turn uneven floors or crooked frames into rock-solid installs without visible gaps.

Woodworking Square

The woodworking square helps you mark perfect 90-degree lines, measure quick angles, or guide your saw for square cuts. Hold it firmly against your workpiece and score lightly first; your layouts will look professional.

Hole Saw

People press too hard and scorch wood or dull the teeth. Let the pilot bit start straight, cut at a moderate speed, and clear sawdust often. You’ll get clean, round holes instead of burned edges and smoking drills.

Owning tools is one thing. Mastering them is another…

Owning tools is one thing. Mastering them is another…

Carpenter’s Pencil

Use the flat sides to keep it from rolling, sharpen it into a chisel tip for crisp marks, and always mark on the waste side of your cut. Your measurements will stop “magically drifting” by a millimeter or two.

Hacksaw

Sawing like you’re chopping firewood will dull the blades. The teeth must face forward, away from the handle, and cut only on the push stroke. The mistake is not setting the blade tension high enough.

Angle Grinder

This tool is powerful but can be misused easily. Always match the wheel to the material, let it reach full speed before touching down, and move steadily without digging in. You’ll be able to grind, polish, or cut without unnecessary sparks flying.

Time to get serious about safety and efficiency!

Time to get serious about safety and efficiency!

Staple Gun

Stapling too close to the edges or pressing at an angle can lead to jams and bent staples. Hold it square, apply firm pressure, and test on scrap first. This way, every staple will land clean and flush.

Pry Bar / Cat’s Paw

The cat's paw (also known as a curved end) is for pulling nails with exposed heads. Tap the claw under the nail or trim gently to protect the surface with scrap wood, and use slow, steady pressure.

Allen Keys / Hex Keys

The most common mistake people make is to round out screws by using the wrong size or by tilting the wrench. Always seat the key fully and keep it straight, and apply a dab of penetrating oil to loosen the bolts if needed.

The next entries are game-changers!

The next entries are game-changers!

Dolly / Hand Truck

The key to safe moving is balance. Tilt the load backward slightly so the weight rests over the axle, not directly on your arms. Secure the object with a strap and move slowly over thresholds and uneven surfaces.

Hose Clamp

Tightening until it bites into the hose will ruin the seal. Position the clamp just behind the barb, snug it evenly, and stop when the rubber bulges slightly. Done right, the connection will stay tight without slicing your hose.

Masonry / Concrete Trowel

Hold the trowel at a slight angle, scoop only what you can control, and spread in steady strokes. With a light touch and patience, your brickwork or slab finishes look crisp instead of clumpy.

Power Jigsaw

Most blades cut on the upstroke, which splinters the top surface. Instead, let the blade do the work: set the right speed, drill pilot holes for inside cuts, and guide steadily for smooth, splinter-free lines.

A neat trick you’ll wish you knew sooner…

A neat trick you’ll wish you knew sooner…

Pipe Wrench

The pipe wrench is designed to grip rounded material (pipes) and bite deeper with pressure. The rule is to apply force in the direction that tightens the adjustable jaw to prevent slippage and get maximum grip.

Heat Gun

The heat gun is not a hairdryer, and should not be held in one spot. Keep the gun moving constantly in small circles to apply even heat. You’ll soften paint, loosen glue, or shrink tubing without scorching everything.

Reciprocating Saw

Think of it as the demolition champion of power tools. It’s made to slice through wood, metal, or pipes at speed rather than delivering perfect edges. Match blade size and type to your material and let the saw do the work.

Headlamp or Work Light

Good lighting is crucial for safety and accuracy. Position your light source so the beam is aimed across your workpiece, rather than straight down. This technique will highlight shadows and help spot imperfections with ease.

Nail Gun

The most common mistake is setting the pressure/depth incorrectly. Set the right depth, keep the nose square to the surface, and always check what’s behind before firing. Short, controlled bursts always beat rapid-fire.