A Well-Organized Toolbox That Went Everywhere

Your grandfather's metal toolbox had a specific place for every tool, and he could find what he needed by feel alone in a dark basement. This organization came from decades of reaching for the same spots, creating muscle memory that made repairs faster. The toolbox itself was built like a tank - heavy gauge steel that could take a beating and protect expensive tools inside. He carried it to every job around the house, whether fixing a leaky faucet or building a backyard shed. Modern plastic toolboxes with their molded compartments try to replicate this organization, but they lack the durability and simple design that made those metal boxes last for generations. Your grandfather knew exactly what he had and where to find it, a system that eliminated wasted time searching through drawers or making extra trips to the garage.

Multiple Sizes of Adjustable Wrenches

He could glance at a bolt and know exactly which crescent wrench to grab, adjusting it with a quick twist while the other hand was already positioning it. No trial and error, no fumbling with different sizes - experience taught him to judge dimensions accurately by sight. Your grandfather kept at least three adjustable wrenches in different sizes because they handled countless jobs without needing a complete socket set. The 6-inch lived in his pocket for small work, the 10-inch stayed in the toolbox for most jobs, and the hefty 12-inch tackled stubborn plumbing nuts. He understood that forcing an oversized wrench rounded bolt heads and created bigger problems. These wrenches were the Swiss Army knife of his tool collection, adapting to whatever fastener size a repair demanded while taking up minimal space.

A Heavy-Duty Claw Hammer

Your grandfather held nails between his lips while hammering, feeding them to his free hand in rhythm without breaking stride. This practice would horrify modern safety inspectors, but it kept work moving efficiently when you had dozens of nails to drive. His hammer was a simple tool - solid steel head, wooden handle worn smooth from years of gripping, perfectly balanced for all-day use. That same hammer could drive 16-penny nails into studs, pull bent nails with its claw, and serve as a persuader for stuck parts that needed gentle encouragement. He never needed a whole collection of specialized hammers because this one workhorse handled everything. The wooden handle absorbed shock better than modern fiberglass, and when it eventually broke, he could replace it himself for pennies.

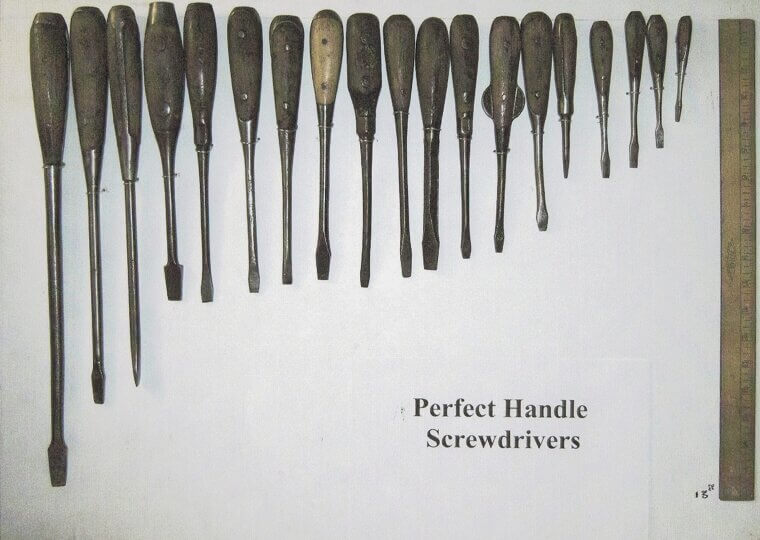

Flathead and Phillips Screwdrivers in Every Size

He'd test a screw head with his thumbnail first, then grab the exact screwdriver that fit without rummaging through the toolbox. Experience taught him that forcing the wrong size stripped screw heads and created problems that took ten times longer to fix. Your grandfather had a complete set of manual screwdrivers before power drills dominated every repair job. The handles were color-coded or marked with tape so he could identify sizes at a glance. He kept them sharp by occasionally filing the tips, ensuring they gripped screw slots properly instead of slipping. Those screwdrivers also served double duty - prying open paint cans, scraping off old caulk, marking measurements on wood. Modern multi-bit screwdrivers try to replicate this versatility, but nothing matched the solid feel and reliability of individual tools built to last.

Pliers in Several Varieties

Channel-locks hung from his belt loop on a leather thong, needle-nose stayed in his shirt pocket - your grandfather positioned tools on his body like a surgeon arranged instruments. He understood that different jobs needed different jaw configurations and gripping surfaces. Needle-nose pliers reached into tight spaces and held small parts precisely. Channel-locks adjusted for various pipe sizes and provided the leverage needed for stubborn plumbing connections. Regular slip-joint pliers handled everyday gripping and twisting tasks. He could grab the right pair without looking because their shapes and weights were distinct in his hand. Modern multi-tools try to combine all these functions, but your grandfather knew that dedicated tools performed better than compromise designs. Those pliers lasted decades because they were simple, rebuildable, and designed to do one job perfectly.

A Hand Saw That Actually Cut Straight

He sharpened his saw teeth with a triangular file every few months, counting strokes to keep the set even and the cutting edge consistent. This meditative ritual turned a basic crosscut saw into a precision instrument that could handle lumber cuts without electricity. Your grandfather knew how to adjust the tooth set for different woods - aggressive for softwoods, finer for hardwood. He'd mark his cut line with a pencil, score it with a utility knife, then follow that groove to start the saw perfectly straight. Modern circular saws are faster, but they can't match the control and quiet accuracy of a well-maintained hand saw. He could make cuts in situations where power tools weren't practical, and the saw never needed batteries or extension cords. That skill and tool independence defined an entire generation's approach to home repair.

A Level That Didn't Need Batteries

Your grandfather could eyeball level pretty accurately after years of practice, but he still checked with his bubble level because experience taught him not to trust assumptions. That simple wooden or aluminum level relied on physics - trapped air bubbles floating in curved glass vials filled with liquid. He'd set it on a surface, wait for the bubble to settle, then adjust until it centered perfectly between the lines. No batteries to die, no lasers to calibrate, no electronics to malfunction. He taught you to check level in multiple spots because floors and surfaces weren't always flat. Modern digital levels flash numbers and beep, but they can't match the reliability of a tool that works the same way it did seventy years ago. His level still hangs in garages today, ready to ensure the next generation hangs shelves straight.

WD-40 and 3-In-One Oil

He kept a rag in his back pocket specifically for wiping excess oil, and could spray WD-40 in tight spaces without overspray - precision developed through thousands of squeaky hinges. Your grandfather understood the difference between penetrating oil for breaking loose stuck parts and light machine oil for ongoing lubrication. WD-40 freed rusty bolts and displaced moisture from electrical connections. 3-in-One Oil lubricated door hinges, tool mechanisms, and anything that moved repeatedly. He applied oil sparingly because too much attracted dust and created gummy buildup. A quick shot in the right spot fixed problems that seemed major, saving money on parts that just needed lubrication. Modern penetrating oils and lubricants offer specialized formulas, but your grandfather proved that two basic products handled nearly every situation when applied with knowledge and restraint.

Electrical Tape and Wire Nuts

Your grandfather twisted wire connections with his fingers in a specific direction, wrapped tape in overlapping spirals, and tested every connection with a gentle tug - habits that prevented house fires. He kept multiple colors of electrical tape to mark different circuits and phases. Wire nuts came in various sizes for different wire gauges, and he knew which size fit which connection without checking the package. Before making any electrical repair, he'd flip the breaker and test with a voltage tester, never assuming a circuit was dead. He understood that proper wire connections required clean copper, tight twists, and secure wire nuts. Modern push-in connectors are faster, but your grandfather's careful method created connections that lasted for decades. Those supplies stayed ready in his toolbox because minor electrical repairs didn't always require calling an electrician.

A Bucket of Assorted Nails, Screws, and Bolts

He could identify screw threads and nail gauges by rolling them between his fingers, knowing instantly if something would work for the job at hand. His fingertips were a measuring system calibrated through decades of repairs. Coffee cans organized by size held hardware salvaged from every project - why buy new fasteners when you probably already had the right one somewhere? He'd dump a can on his workbench, sort through by feel, and find what he needed faster than driving to the hardware store. Those collections included specialty fasteners that stores no longer stocked, making them invaluable for repairing older items. Modern organizing systems with labeled drawers try to replicate this, but they lack the economy of reusing what you already have. Your grandfather understood that saving hardware was saving money, and his fingertip knowledge made that system work efficiently.

A Sturdy Stepladder

Your grandfather always positioned his ladder at the correct angle without measuring - one boot-length out from the wall for every four feet up, a ratio learned through muscle memory. He'd shake the ladder before climbing to ensure it sat solid, and never stood on the top two rungs despite what the warning labels said. His wooden or aluminum ladder was heavy enough to be stable but light enough to carry easily. He understood ladder safety through experience rather than training videos. The rubber feet gripped floors without slipping, and the spreader bars locked firmly to prevent collapse. Modern fiberglass ladders are lighter and don't conduct electricity, but they lack the simple reliability of those older designs. Your grandfather would never trust those flimsy折叠 models that fold up into compact packages, knowing that stability matters more than storage convenience.

A Sharp Utility Knife

Your grandfather stropped his utility knife blade on his leather belt between uses, keeping it sharp enough to slice through materials cleanly rather than tearing them. A sharp blade required less pressure and made cleaner cuts, reducing mistakes and injuries. That retractable knife handled everything from opening packages to scoring drywall to trimming materials precisely. He changed blades at the first sign of dullness because forcing a dull blade caused it to slip and cut things it shouldn't - including fingers. The knife stayed in a specific pocket so he always knew where to reach for it. Modern safety knives with auto-retracting blades try to prevent injuries, but your grandfather's careful habits kept him safe for decades. He taught that respecting tools meant maintaining them properly and using them with focus, lessons that applied to every item in his toolbox.