Skipping Safety Glasses While Cutting

It's tempting to skip safety glasses for "just one quick cut," especially when you're in the middle of a project and feeling confident with your tools. But even experienced woodworkers know that sawdust, wood chips, and metal fragments can fly in unexpected directions. Your eyes are irreplaceable, and the few seconds it takes to put on safety glasses could save your vision. Modern safety glasses are lightweight, affordable, and designed to be comfortable for extended wear. Keep several pairs around your workshop so you'll never have an excuse to skip this crucial step. Anti-fog versions work especially well during intense projects when you're working up a sweat. Make it a habit to put them on before you even plug in your tools—that way, protection becomes automatic rather than an afterthought

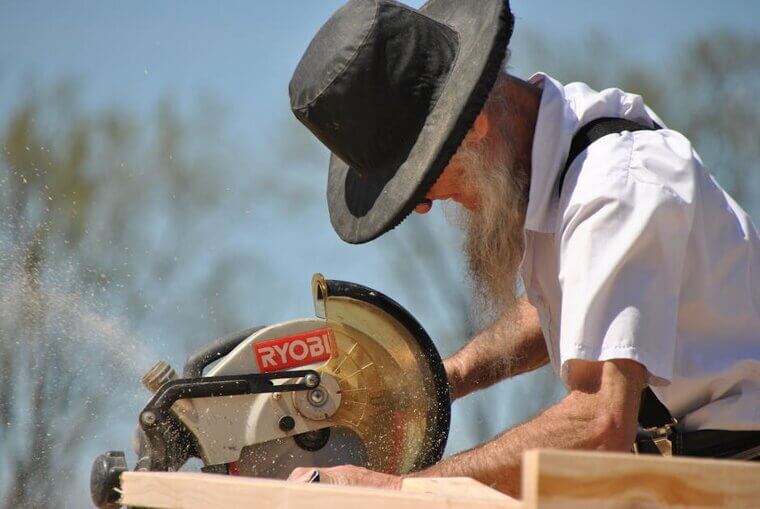

Wearing Loose Clothing Near Machinery

That comfortable hoodie or loose-fitting jacket might seem perfect for a day in your workshop, but it could become a serious hazard around rotating machinery. Loose sleeves, dangling drawstrings, and untucked shirttails can catch on spinning blades, drill bits, or lathe components faster than you can react. The solution is simple: wear fitted clothing when working with power tools. Roll up long sleeves securely or switch to short sleeves. Tuck in shirts and remove any jewelry, watches, or dangling items. Remember those old shop class rules from high school? They weren't being overly cautious—they were based on real accidents that happened to people who thought it wouldn't happen to them. Your grandfather might have worked in his workshop wearing whatever was comfortable, but he also knew to respect rotating machinery with common-sense clothing choices.

Neglecting to Unplug Power Tools

Simply switching off your table saw might seem sufficient, but that spinning blade can become a serious hazard if someone accidentally bumps the power switch while you're changing blades or making adjustments. The extra step of unplugging tools before maintenance takes just seconds and removes all possibility of accidental startup. This habit becomes especially important if you have curious grandchildren who visit your workshop or helpful neighbors who might not understand which tools are "off" versus truly safe to approach. Make unplugging part of your routine—as automatic as putting on safety glasses. Some woodworkers even keep a brightly colored tag that says "Unplugged for Maintenance" to remind themselves and others that work is in progress. It's a simple precaution that costs nothing but could prevent a life-changing accident.

Working Without Proper Dust Protection

That cloud of sawdust billowing up from your miter saw might not seem concerning at first, but breathing in wood particles over time may affect respiratory health. Many weekend woodworkers skip the respirator because it feels uncomfortable or seems unnecessary for short projects. However, fine dust particles can penetrate deep into your lungs, and the effects accumulate over years of exposure. A quality dust mask or respirator costs less than dinner out and provides protection that your lungs will thank you for decades from now. Look for masks rated N95 or higher for fine particle filtration. If you're working with treated lumber, exotic woods, or creating large amounts of dust, upgrade to a proper respirator with replaceable filters. Pair your mask with good ventilation—open your garage door or workshop windows to keep air flowing and dust levels down.

Ignoring Frayed or Damaged Cords

Damaged electrical cords create serious shock and fire hazards in your workshop. Frayed cords don't always show obvious signs of danger until it's too late. That small nick in the insulation or slightly worn section near the plug might seem minor, but it creates a path for electricity to escape where it shouldn't. Make it a habit to inspect all your power cords before each use, running your hands along their length to feel for damage you might not see. Pay special attention to the areas where cords connect to plugs and tools—these high-flex zones wear out first. If you find any damage, replace the cord immediately rather than wrapping it with electrical tape as a temporary fix. Quality replacement cords are inexpensive compared to the cost of electrical fires or serious shocks. Your future self will appreciate taking this simple precaution seriously.

Removing Safety Guards From Equipment

Taking off blade guards might save a few seconds on each cut, but those seconds aren't worth risking serious injury. Many woodworkers develop overconfidence after years without incidents, convincing themselves that guards just get in the way of seeing their work. The truth is, guards are engineered specifically to protect you while allowing proper tool operation. Modern safety guards are well-designed and don't significantly impede your ability to work effectively. If a guard seems to interfere with your project, the solution is finding the right technique or jig—not removing the protection. Those old-timers who worked without guards? Many of them also have missing fingers and cautionary tales about the accidents they wish they could undo. Keep your guards in place and keep all your fingers for the projects ahead.

Poor Workshop Lighting Creates Hazards

Working in dim conditions transforms even routine tasks into potential hazards. When you can't clearly see what you're doing, your chances of cuts, pinched fingers, and tool mishaps multiply dramatically. That single overhead bulb might have been enough when you first set up your workshop, but proper lighting means having bright, shadow-free illumination exactly where you need it. Install task lighting directly over your workbenches, table saw, and other primary work areas. LED shop lights are affordable, energy-efficient, and provide the bright white light that helps you see details clearly. Consider adding adjustable lamps that you can position for specific tasks. Good lighting isn't just about safety—it also improves the quality of your work by helping you spot mistakes before they become problems. Your eyes will thank you, and your projects will turn out better.

Cluttered Workbenches Lead to Injuries

A cluttered workbench isn't just an eyesore—it creates genuine safety hazards. When your tools are piled haphazardly or hanging without proper organization, you're setting yourself up for accidents. That chisel buried under lumber scraps can slice your hand when you reach for something else. Tools rolling off the edge can land on your feet or break. Clutter also forces you to work in awkward positions, increasing the chance of mistakes. Take time at the end of each session to return tools to their designated spots and clear away scrap materials. Install pegboards, tool racks, and storage solutions that keep everything visible and accessible. A clean workspace isn't about being neat—it's about creating an environment where you can focus on your project instead of navigating obstacles. Remember how your father always insisted on cleaning up before dinner? That habit makes even more sense in a workshop filled with sharp tools and powerful machinery.

Using Dull Blades Increases Risk

A dull blade actually poses more danger than a sharp one. When your saw blade loses its edge, you're forced to apply extra pressure to make cuts, which means less control over the tool. That extra force can cause the blade to bind, kick back, or skate across the material instead of cutting cleanly. Dull blades also create more heat from friction, which can scorch wood and even damage your tools. Make blade sharpening and replacement part of your regular maintenance routine. Keep spare blades on hand so you can swap them out immediately when you notice cutting performance declining. Yes, quality blades cost money, but they're far cheaper than emergency room visits or ruined projects. Your cuts will be cleaner, safer, and require less effort when you're working with sharp tools. Professional woodworkers know this, which is why they never compromise on blade condition.

Working Alone Without an Emergency Plan

Working by yourself in the workshop might feel like the perfect way to focus on your project, but it creates risks if something goes wrong. Before you head out to your workspace alone, make sure someone knows where you'll be and when to expect you back. Keep your phone charged and within reach—not buried under sawdust on a distant workbench. Consider investing in a personal alarm system or smart device that can detect falls. Many modern smartwatches include emergency features that can call for help automatically. Set up a simple check-in system with your spouse or a neighbor—a quick text when you start and finish takes just seconds. Your independence in the shop is valuable, but your safety matters more. These precautions let you work alone with confidence, knowing that help can reach you if needed.

Failing to Secure Workpieces Properly

Holding a piece of wood steady with one hand while cutting isn't secure enough, and that's when accidents happen. When your workpiece shifts even slightly during a cut, your blade can bind, kick back, or pull toward your hand. Always use clamps, vises, or hold-downs to secure your materials before making any cuts. Your table saw likely came with a miter gauge and rip fence for good reason—they're designed to keep wood stable and your hands at a safe distance. If you're working with smaller pieces, invest in push sticks and featherboards. These simple tools cost far less than medical bills and give you the control you need for clean, safe cuts every time. Remember learning in shop class that both hands should be clear of the cutting path? That wisdom still holds true.

Storing Flammable Materials Near Heat Sources

Placing that can of paint thinner on the shelf closest to your space heater might seem convenient, but this oversight has been identified as a fire risk in workshops. Flammable liquids like gasoline, starter fluid, transmission fluid, and oil-based paints need to be stored in cool, well-ventilated areas away from any heat source. That means keeping them far from furnaces, water heaters, electrical panels, and even direct sunlight streaming through windows. The fumes from these products are often more dangerous than the liquids themselves, creating vapor clouds that can ignite from a spark or flame several feet away. Make it a habit to designate a specific storage area in the coolest part of your workshop, preferably in a metal cabinet designed for flammable materials. Your future self will thank you for taking this simple precaution seriously.

Not Using Hearing Protection

The high-pitched whine of a circular saw can reach sound levels that may be harmful to hearing according to safety standards. Yet many woodworkers skip this simple safety step, thinking they'll only be cutting for a moment or that their hearing is already affected. The truth is, every exposure adds up, and hearing damage is irreversible. Persistent ringing or hearing difficulties may be related to years of noise exposure. A simple pair of foam earplugs or noise-canceling earmuffs costs just a few dollars and can help preserve your hearing for the decades ahead. Many modern earmuffs even include built-in speakers so you can listen to music while protecting your ears. Make hearing protection as automatic as putting on safety glasses—grab it before you grab your tools. Your future self will thank you for taking this precaution seriously today.

Rushing Through Projects Without Planning

When you're eager to complete a project, it's tempting to fire up your tools and dive right in. But that impatience can lead to mistakes and safety issues. Without taking time to plan your cuts, measure twice, and think through each step, you're setting yourself up for problems. Before you start any cutting, grinding, or assembly work, take fifteen minutes to map out your approach. Check that your safety gear is secure, clear away clutter, and mentally walk through the entire process. Make sure your workspace is properly prepared and all materials are within easy reach. Your project will turn out better, and you'll work more safely. Remember, professional craftsmen know that preparation time is never wasted time. Those extra minutes of planning save hours of fixing mistakes and help prevent injuries that could sideline your woodworking for weeks.

Missing First Aid Kit Essentials

A first aid kit hanging on your workshop wall is only useful if it's properly stocked and current. Too many of us assume that box is ready for action, only to discover during an emergency that it's missing crucial supplies or everything expired years ago. Your workshop first aid kit needs more than just adhesive bandages. Stock it with gauze pads for larger cuts, antiseptic wipes, tweezers for splinters, and burn gel for unexpected encounters with hot metal or soldering irons. Include eye wash solution and disposable gloves. Make it a habit to inspect your kit every six months, replacing used items and checking expiration dates. Write the inspection date right on the kit so you'll remember. When you're working with power tools and sharp materials, a well-stocked first aid kit is essential preparation for handling minor injuries quickly and effectively.